When selecting a mainline hose for moving manure in commercial farming, there are several important factors to consider. These factors will help ensure efficient and reliable manure transfer while minimizing the risk of hose failure and environmental contamination. Here are the key considerations:

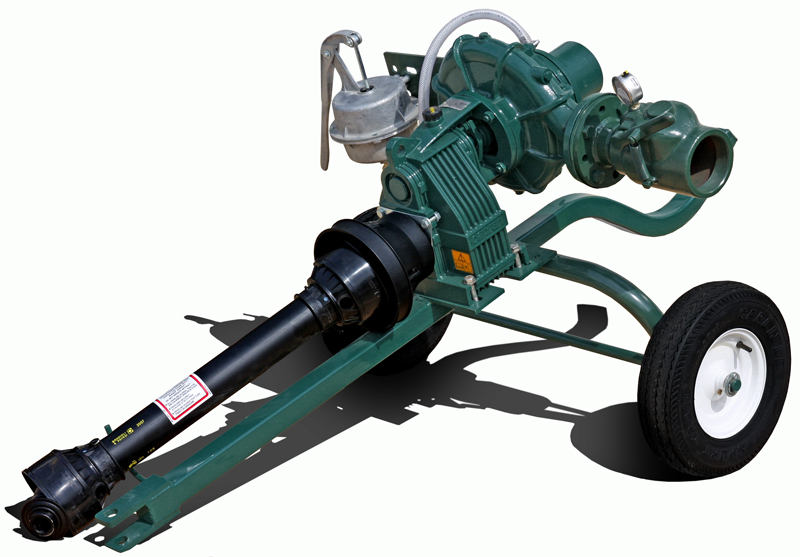

Mandals Mainline Hose

- Hose Material: Choose a hose material that is specifically designed for handling manure and is resistant to chemicals, abrasion, and punctures. Common materials used for manure hoses include synthetic rubber blends or polyethylene (PE).

- Diameter and Length: Consider the required flow rate and the distance the manure needs to be transported. Larger diameter hoses allow for higher flow rates, while longer hoses may be necessary to reach various areas of the farm. Ensure the hose length and diameter match your specific needs.

- Pressure Rating: Determine the maximum pressure the manure hose will be subjected to during operation. Select a hose with a pressure rating that exceeds the maximum pressure anticipated in your system. It’s crucial not to exceed the manufacturer’s recommended pressure to prevent hose failure.

- Flexibility and Bend Radius: Evaluate the hose’s flexibility and bend radius to ensure easy maneuverability and proper routing. A more flexible hose with a smaller bend radius will be easier to handle and less prone to kinking or collapsing.

- Corrosion Resistance: Manure can contain corrosive substances, so it’s essential to choose a hose that is resistant to corrosion. Look for hoses with appropriate coatings or liners that provide protection against corrosive elements.

- Smooth Interior: Select a hose with a smooth interior surface to minimize friction and prevent clogging or buildup of manure solids. A smooth interior also facilitates easier cleaning and maintenance.

- UV Resistance: If the hose will be exposed to sunlight or outdoor conditions, choose a hose with UV resistance to prevent degradation and premature failure due to sun exposure.

- Couplings and Fittings: Consider the compatibility of the hose with your existing manure handling system fittings and connections. Ensure the hose has the appropriate fittings and connections for easy integration and secure connections.

- Safety Features: Look for hoses that meet safety standards and regulations, such as those designed to minimize the risk of leakage, spills, or odors. Consider features like double-walled construction or leak-proof couplings.

- Price and Warranty: Compare the price of the hose in relation to its quality and features. Additionally, check the warranty offered by the manufacturer to ensure you have recourse in case of manufacturing defects or premature failure.

By considering these factors, you can select a mainline hose that is durable, efficient, and reliable for moving manure in commercial farming. Remember to consult with experts or industry professionals for specific recommendations based on your farm’s unique requirements.

While we have access to other hose manufacturers, we primarily sell Mandal’s Mainline Hoses and Mandal’s Drag hoses.

CLICK HERE to order Mainline Hose or CLICK HERE to order Drag Hose online, or feel free to give us a call today at 517-458-9741!