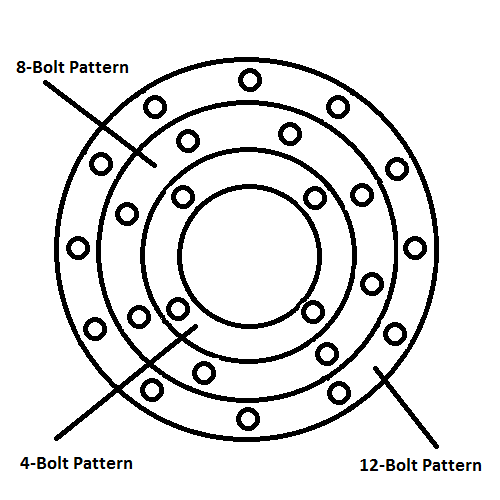

Steel Welding Flanges are available in several sizes. Please note the bolt pattern differs depending on which size you choose. Each of the steel welding flanges are 1/2″ OD Pipe Size.

| 2″ Welding Flange Pipe Size = 2″ OD = 6″ Thickness = 1/2″ Bore = 2.06″ # of Holes = 4 |

2-1/2″ Welding Flange Pipe Size = 2-1/2″ OD = 7″ Thickness = 1/2″ Bore = 2.56″ # of Holes = 4 |

3″ Welding Flange Pipe Size = 3″ OD = 7-1/2″ Thickness = 1/2″ Bore = 3.06″ # of Holes = 4 |

4″ Welding Flange Pipe Size = 4″ OD = 9″ Thickness = 1/2″ Bore = 4.06″ # of Holes = 8 |

| 5″ Welding Flange Pipe Size = 5″ OD = 10″ Thickness = 1/2″ Bore = 5.06″ # of Holes = 8 |

6″ Welding Flange Pipe Size = 6″ OD = 11″ Thickness = 1/2″ Bore = 6.06″ # of Holes = 8 |

7″ Welding Flange Pipe Size = 7″ OD = 11″ Thickness = 1/2″ Bore = 7.06″ # of Holes = 8 |

8″ Welding Flange Pipe Size = 8″ OD = 13-1/2″ Thickness = 1/2″ Bore = 8.06″ # of Holes = 8 |

| 10″ Welding Flange Pipe Size = 10″ OD = 16″ Thickness = 1/2″ Bore = 10.06″ # of Holes = 12 |

12″ Welding Flange Pipe Size = 12″ OD = 19″ Thickness = 1/2″ Bore = 12.06″ # of Holes = 12 |

OD = Outside Diameter |  |

Brand Name: Pierce

In irrigation systems, steel welding flanges are used to connect pipes, valves, pumps, and other equipment in a secure and leak-proof manner. These flanges are typically welded to the ends of steel pipes, allowing for the assembly and disassembly of various components without the need for threading or other types of connections. Here are some key uses and advantages of steel welding flanges in irrigation:

- Secure Connections: They provide a strong and durable connection between pipes and other equipment, ensuring that the system can handle high pressures and large volumes of water without leaking.

- Ease of Maintenance: Welding flanges allow for easy disconnection of pipes and equipment, which simplifies maintenance and repair tasks. This is particularly useful in large or complex irrigation systems where components may need to be replaced or serviced regularly.

- Alignment and Flexibility: Flanges can be used to align pipes correctly during installation. They also allow for slight adjustments and misalignments, accommodating the natural expansion and contraction of metal pipes due to temperature changes.

- Compatibility with Various Components: Steel welding flanges can be connected to a variety of other components in an irrigation system, including valves, pumps, and filters, providing versatility in system design and modification.

- Strength and Durability: Made of steel, these flanges are highly resistant to mechanical stress and corrosion, ensuring a long service life even in demanding agricultural environments.

- Leak Prevention: When properly welded and installed, steel welding flanges create a robust seal that prevents water leakage, which is crucial for maintaining the efficiency of the irrigation system and conserving water resources.

Overall, steel welding flanges are essential for constructing reliable and efficient irrigation systems, ensuring that water is delivered effectively to crops with minimal loss or interruption.