Venturi Fertilizer Injector Assembly for 1 1/2″, 2″, 3″ or 4″ Line. Please call us for additional sizes and/or options.

A Venturi Fertilizer Injector Assembly is a device used in irrigation systems to introduce liquid fertilizers, pesticides, or other water-soluble solutions into the irrigation water. It operates on the Venturi effect, where a reduction in water pressure creates suction, allowing the injector to draw the fertilizer solution into the irrigation line without requiring an external power source.

Key Features:

- Venturi Injector Mechanism:

- Based on the Venturi principle, the injector creates a pressure differential within the water flow, generating suction to pull fertilizer or additives into the system.

- Efficiently mixes the solution with the irrigation water for even distribution.

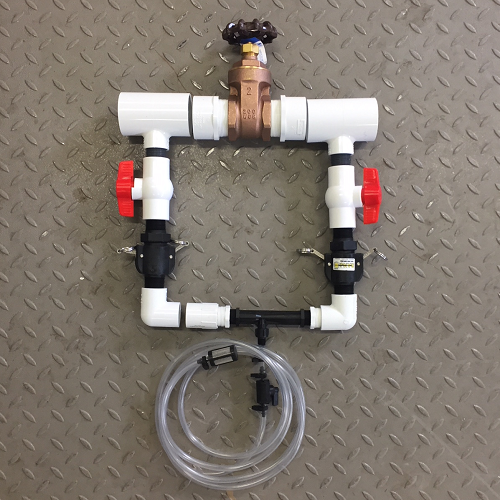

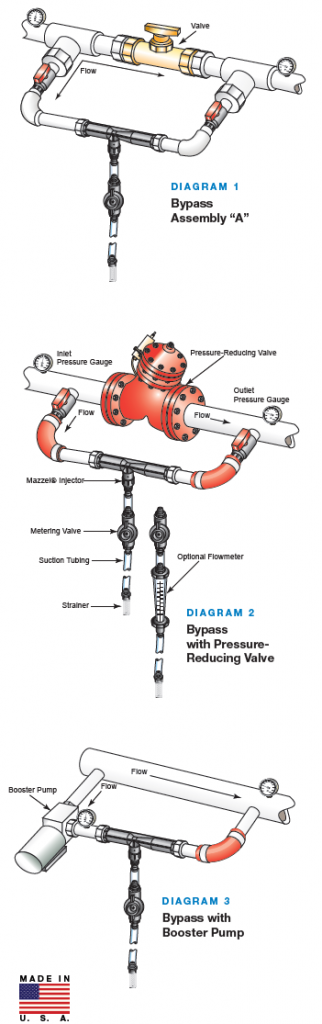

- Complete Assembly:

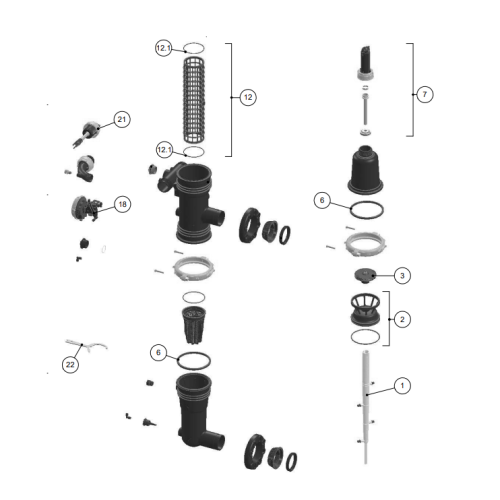

- Typically includes a Venturi injector, a filter to protect against debris, a suction line for drawing the fertilizer, and control valves to regulate water flow and solution injection rates.

- Some assemblies may also include flow meters or pressure gauges for precision control.

- Durable Construction:

- Made from corrosion-resistant materials like plastic, brass, or stainless steel to withstand exposure to chemicals and harsh irrigation environments.

- Compatibility:

- Works with various irrigation systems, including drip, sprinkler, and pivot systems.

- Compatible with most water-soluble fertilizers and liquid additives.

- Energy-Free Operation:

- Requires no electricity or additional power sources, relying solely on the water pressure in the system.

How It Works:

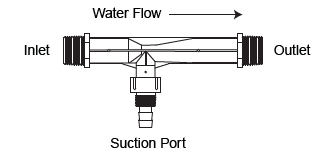

- Water Flow:

- Pressurized water enters the Venturi injector, creating a constriction that reduces pressure and increases velocity.

- Suction:

- The pressure drop generates suction, drawing the fertilizer or solution through the suction line.

- Mixing:

- The solution is mixed with the water in the injector and carried through the irrigation system.

- Delivery:

- Nutrient-enriched water is distributed to plants via the irrigation network.

Benefits:

- Efficient Fertilizer Delivery:

- Ensures nutrients are delivered directly to the plant root zone, enhancing absorption and minimizing waste.

- Cost-Effective:

- Operates without the need for pumps or external power, reducing operational costs.

- Uniform Distribution:

- Provides consistent and even mixing of fertilizer with irrigation water for balanced plant growth.

- Simple and Reliable:

- Easy to install, operate, and maintain, with few moving parts to break or wear out.

- Water and Nutrient Conservation:

- Optimizes resource use and reduces environmental impact by preventing over-fertilization and runoff.

Common Applications:

- Drip Irrigation:

- Ideal for delivering precise nutrients directly to plant roots.

- Greenhouses:

- Supplies exact formulations of fertilizers and additives for controlled plant growth.

- Agricultural Crops:

- Supports even fertilization over large fields, improving yields.

- Horticulture and Landscaping:

- Feeds plants, lawns, and ornamental gardens efficiently.

Differences Between a Venturi Injector and a Venturi Fertilizer Injector Assembly:

- The Venturi Injector is the core device, while the Venturi Fertilizer Injector Assembly includes additional components such as filters, valves, and suction lines for a complete, ready-to-use system.

In summary, a Venturi Fertilizer Injector Assembly is a practical, energy-efficient tool for integrating liquid fertilizers and additives into irrigation systems. Its simplicity, cost-effectiveness, and precise nutrient delivery make it invaluable for modern agriculture, landscaping, and greenhouse operations.