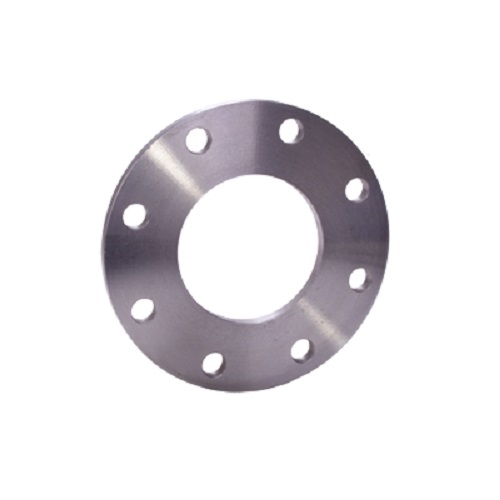

A Cast Iron Companion Flange is a type of pipe fitting used in irrigation, plumbing, and industrial systems to provide a secure and leak-proof connection between pipes, pumps, or valves. It features a flat, circular design with bolt holes for fastening to a mating flange, ensuring a stable and tight seal. Made from durable cast iron, it is suitable for heavy-duty applications, especially in systems handling high pressure or large volumes of water.

Key Features:

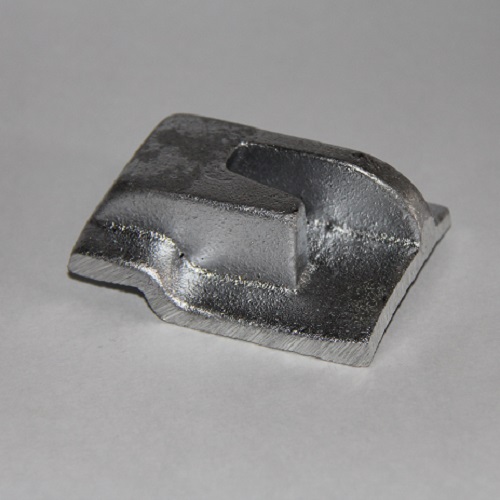

- Material – Cast Iron:

- Known for its strength and durability, cast iron provides excellent resistance to mechanical stress, making it ideal for demanding environments.

- Naturally resistant to wear and corrosion when properly coated or maintained.

- Flat, Flanged Design:

- The flat surface of the flange creates a solid sealing area, while the bolt holes allow for secure fastening to another flange or component.

- Often used with gaskets to ensure a watertight connection.

- Companion Flange Configuration:

- Designed to align perfectly with another flange (or “companion flange”) for seamless integration into a piping system.

- Standardized Sizing:

- Manufactured to standard pipe flange dimensions (e.g., ANSI, ASME), ensuring compatibility with other standard components.

- Bolt Holes:

- Equipped with multiple bolt holes to evenly distribute clamping force, reducing the likelihood of leaks or misalignment.

Common Applications:

- Irrigation Systems:

- Connects pipes or hoses to pumps, valves, or mainlines in agricultural and landscape irrigation setups.

- Pumping Stations:

- Provides a secure connection between suction or discharge pipes and irrigation pumps.

- Water Distribution:

- Used in municipal and industrial water systems for connecting pipes or fittings.

- Drainage Systems:

- Ideal for handling wastewater or stormwater in drainage setups.

- Industrial Piping:

- Connects pipes and valves in systems handling fluids, chemicals, or gases.

Benefits:

- Durability:

- Cast iron construction ensures long-lasting performance under heavy-duty conditions.

- Secure Connections:

- The flange design provides a tight seal, especially when paired with a gasket, minimizing leaks.

- Pressure Resistance:

- Capable of handling high pressures, making it suitable for both irrigation and industrial applications.

- Versatility:

- Compatible with a variety of pipes, valves, and other components.

- Ease of Installation:

- Standardized design simplifies installation and maintenance, ensuring a precise fit with other system components.

How It Works:

- Alignment:

- Position the companion flange so that its bolt holes align with those of the mating flange.

- Gasket Placement:

- Insert a gasket between the two flanges to create a watertight seal.

- Fastening:

- Use bolts and nuts to secure the flanges together, evenly tightening to prevent leaks or uneven connections.

- Testing:

- Check for leaks and proper alignment after assembly.

Key Considerations:

- Pipe Compatibility:

- Ensure the flange size and pressure rating match the system’s requirements.

- Gasket Selection:

- Use an appropriate gasket material based on the fluid type and system conditions.

- Corrosion Protection:

- Consider coated or lined cast iron flanges for applications involving corrosive fluids or harsh environments.

- Pressure and Temperature Ratings:

- Verify that the flange meets the operating conditions of the system.

In summary, a Cast Iron Companion Flange is a robust and reliable fitting used to connect pipes and components in irrigation, water distribution, and industrial systems. Its durable construction, secure sealing, and versatility make it a valuable part of any piping infrastructure