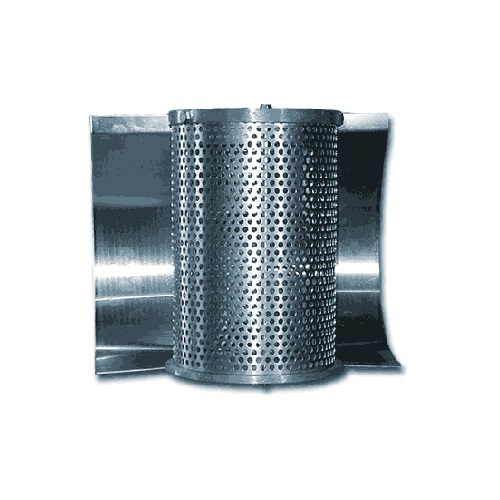

This is an intake strainer – Basic – OD Tubing.

This easily and quickly attached to the end of the aluminum suction pipe by drilling three holes in the tubing and inserting bolts.

This is made of aluminum castings and perforated sheet aluminum, these strainers are lightweight, yet sturdy and durable.

Heavy gauge sheet aluminum slide eliminates need for tub or pail under the strainer.

This also permits sliding the suction pipe into and out of the water. In some cases the slide may be turned over and used as a swirl stopper.

*Be sure to check out our full line of Sure-Flo Fittings & Replacement Parts!*

Watch our video: Strainers Explained

Brand Name: Sure-Flo Fittings